The Brains Behind the Cyclone Dual Sector Gear

Dom

02 Aug 2010

Cyclone dual sector gear: It's not the newest thing out there but it's certainly one of the craziest ideas I've ever seen since I started playing airsoft. When you think there is no room for improvement someone always comes up with a mind blowing innovation. This is exactly what RiotSC (Danny) did: he re-invented the sector gear in order to achieve extreme rate of fire with AEGs.

Popular Airsoft: First of all please introduce yourself and explain what Cyclone is about.

Danny: My name is Danny Huang, and I am the owner of the airsoft company Siegetek Concepts based in California. I design and produce high strength gears for TM and compatible AEGs.

Are you a "one man army" or other people helped in the design?

I have been doing pretty much everything on my own since I dived into the airsoft business 5 years ago. I certainly wished that I could be as effective as a “one man army,” as I frequently run into issues in the execution. Designing/creating products and running a business are both continuous learning experiences for me. I probably would not have made it this far without the help from various people. I have to specifically thank Carl of Airsoft Innovations for offering me his insights and expertise when I was stuck at various times. His pointers got me out of thought gridlocks in quite a few occasions.

Do you still remember the moment when the idea of the Cyclone first popped out of your head?

I do not remember the exact moment anymore, but it was even before I decided to start my own airsoft business. Back then, people just started experimenting with short stroking for high ROF builds. The idea was that by decreasing the number of sector gear and piston teeth, the piston assembly would gain additional time to return to rest state while having a shorter distance to travel. The modification decreased the likelihood of sector gear and piston engagement errors with an added bonus of slight increase in ROF due to the lower motor loading from the short stroke.

I did not jump on the bandwagon however due to the overall energy efficiency loss. The ROF gain was only about 3% increase while the energy output loss was almost 10% per tooth removed. Then it occurred to me, why not make use of the expanded empty sector on the sector gear to reclaim some of the energy. After some experimentation, the dual-sector gear concept was born.

How long did it take to develop the final version of your dual sector gear? I guess you ruined a couple of parts along the way. Are you still counting how many pistons, motors, gearboxes and other parts you rendered useless?

It took about 3 years on and off to get to the current version after I decided to commercialize it. On a side note, I update my products whenever I deem necessary, so I never consider any of my designs “final.” I originally did not even plan on turning the dual-sector gear into a product. I only made a couple units for my own entertainment at the beginning, but people started inquiring about it. So eventually I added the dual-sector gear into my product line-up.

As for the failed components, I kept all of them for individual case studies, but I stopped counting the numbers long ago. The boxes of destroyed parts gathered throughout the years weighed almost 30 pounds the last time I checked. I just hope that I do not add more into the piles.

What's the biggest challenge in making your own parts?

My biggest challenge is certainly turning the conceptual designs into physical items. It is quite easy to come up with various product features. However, translating those design ideas into tangible products often require further research and experimentation on the available materials, tools and processes. The worst part is the occasional encounter with the dreaded “what would work in theory might not work in real life” phenomenon. That is why I also spend a lot of time on testing prototypes to make sure that the actual products will function according to my specifications.

You are not only offering one single sector gear but you also have other parts to back up the Cyclone. You don't trust other brands or your design simply works better if it's used with your parts?

I was actually making traditional TM mechbox compatible gear sets before I created the Cyclone product line. Back then, there were not that many brands of aftermarket gear sets available, and I did not appreciate the fact that the aftermarket gear set “upgrades” were still failing so often in my various AEG builds. So I decided to make my own gear sets with better structural designs, materials, and processes.

I also optimized the involute profiles (gear tooth shape) of my gears for each specific gear ratio for the best efficiency and durability. While some of my gears, such as the Cyclone dual-sector gear, were designed to have interoperability with other manufacturers’ gear sets, they still perform most efficiently with my matching gears.

Which brands you recommend?

In terms of aftermarket parts in general, LayLax (Prometheus, Nineball, etc) and Modify are probably two of the most consistent.

Are you planning to release a complete gearbox for the entry level user who cannot complete major upgrades alone?

This one is tough. I will need to find a company to partner with to do so since I specialize in mechanical gears. Diving into other components would mean additional tooling and facilities that I currently cannot afford on my own.

You wrote that during your tests you've reached the limit of the electric motors used in today's AEG. If I give you a better motor today how far you think you could push the Cyclone before other problems occur?

That would totally depend on how much better the motor is. If we could have brushless outrunner motors, then things would be a lot easier. Theoretically speaking, assuming the motor could handle any load, I certainly would not hesitate to push the ROF to 80 rounds per second (RPS) and beyond. Obviously the build would require various additional tuning for reliability, but it would no doubt be doable.

What keeps you going? What is your final goal?

Passion for these devices keeps me going. As for my goal, I would like to eventually make a low maintenance, high performance, and highly reliable AEG. That is the current goal anyway, which is subject to updates as always.

You're still trying to improve the Cyclone or you're running new projects now?

I always look for areas to improve and new projects to experiment. So don’t be surprised if you see a new version Cyclone or other new products appearing out of nowhere…

What was the fastest ROF you ever achieved with an AEG using the conventional gearbox design without FET? Compared to this what the Cyclone is capable of? What was the highest voltage you ever used to drive a gearbox?

Without MOSFET devices, I have gotten up to 46 RPS on a 12V NiCD battery pack way back in the days. Cyclone can accomplish that at lower voltages. As for the highest voltage, I have used 24V before by linking 2 12V lead acid batteries in series, but the linked motors all simply went pop as soon as the trigger was depressed. That was way back in the days when there were only a couple brands of motors available though. So perhaps modern AEG motors can fair better, but I doubt it.

Tell us about your favorite AEG and what roles you like to play? You like close quarters fight or you rather play on MILSIM games?

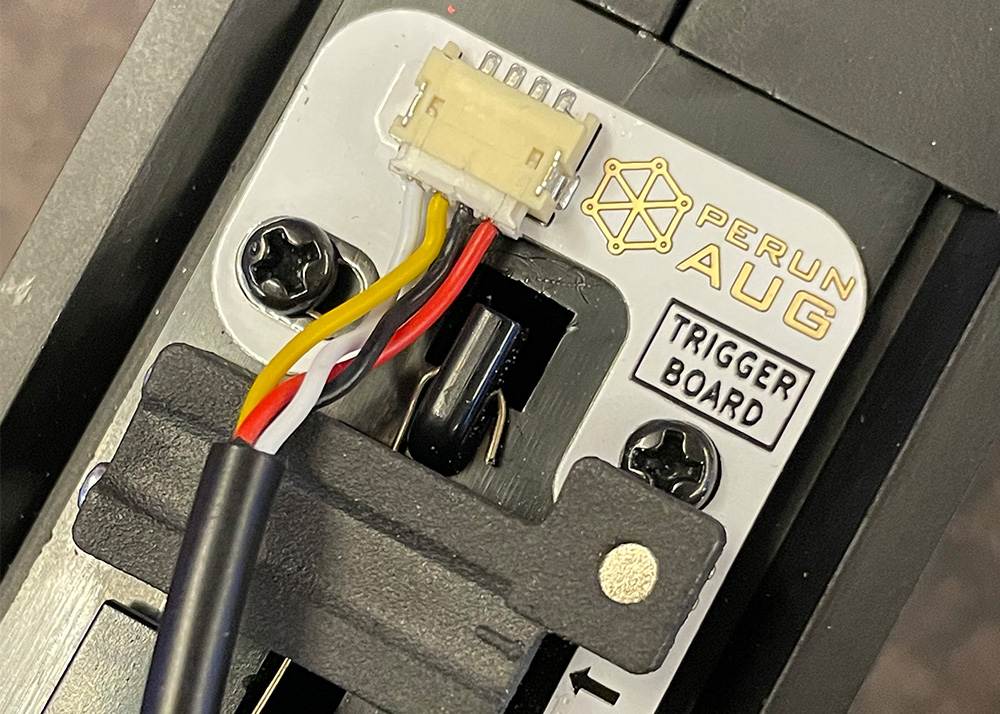

I have to say the TM Steyr AUG. It is by far the most versatile AEG I have used. I have multiple barrel sets and mechboxes for the different performance requirements. Unfortunately, I have not had time for skirmishes for quite a while. So I guess I’ll have to settle for the role of the armorer for now… I am sure I’ll enjoy the different styles of play equally well though if I could find time to get back into the game.

Do you have a team or you are a "freelancer"?

All of the friends I played with moved on to other things in life unfortunately. So I guess I would be a “freelancer.” I need more time first though…

What do you think about the recent hype of GBB rifles?

Realism is one thing airsofters have always been after, so I totally understand the appeal. However, performance consistency and reliability remain areas that leave a lot to be desired for the current generation of GBB rifles. The continuous improvements are promising though.

People can find you on the airsoftmechanics.com forum where you're an admin. Please tell us something about this community/website. Everyone seems to be helpful there and the site is a great source of practical knowledge.

Jay started the website as a technical information source for everything airsoft related. I found Jay’s scientific experiments and approaches to the many fundamental questions extremely helpful, so I started participating in the forum discussions. Before long, I found myself an admin on the site.

Since many of the discussions tend to remain technical, we are able to attract and maintain a certain level of expertise within the community. I certainly hope the community as a whole can help keep the site that way.

Do you know any other independent projects out there what we should check out?

I am pretty sure you are already aware of the projects by the various members on the site: Tornado Grenade by Carl (MadMax), SW series computer controlled MOSFET devices by Terry (Gandolf), battery protection circuits by Kevin (WolfDragon), intelligent MOSFET devices by Frank (PsyphyerVII), MASK series Sorbothane padded cylinder/piston heads by Kashino (Tirador), etc. There are many other independent projects out there. As long as there are people who are not fully satisfied with what are available, there will always be those who are motivated enough to correct the deficiencies.

Hit of the year?

Too early to say, I will need another couple of months.

Failure of the year?

While I would like to say same as above, I highly doubt there would be anything worse for me than losing several contracted facilities. The financial sectors that caused the economic downturn are definitely the biggest failures of the year.

China gun?

Not my cup of tea, but if that is what provides some players tickets into the game, why not, especially in the current economic climate… I just hope people understand that they get what they pay for.

0.20 or 0.25?

In terms BB weight for normal use, I would choose 0.25g for the better stability over 0.2g. 0.2g BBs feed better for high ROF builds though. So it comes down to the application.

Thanks for your answers Danny. Make sure you let us know as soon as you come up with something new!

To find Danny, check the following websites: